|

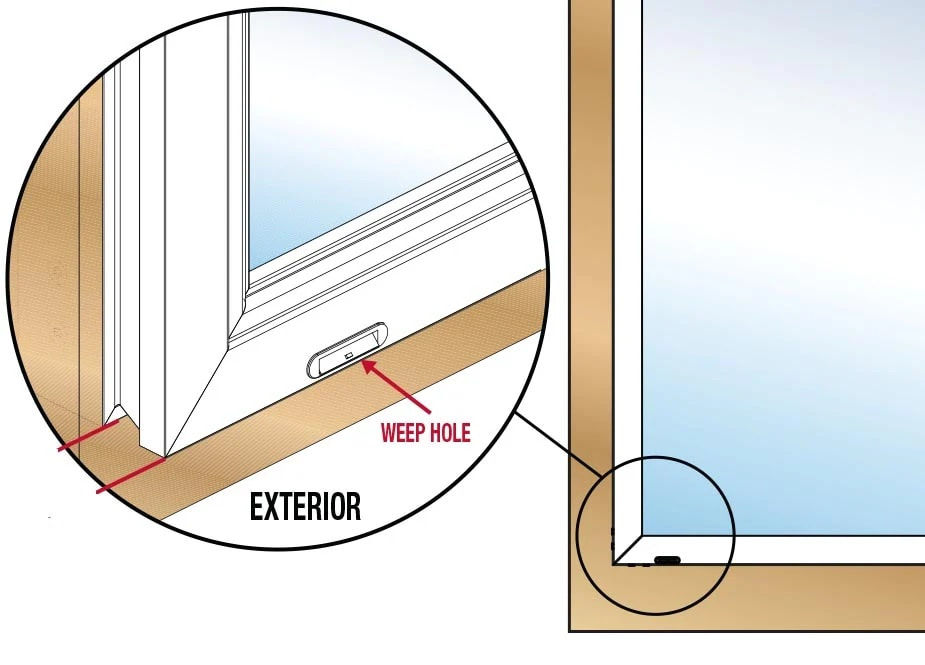

Weep holes, also known as drainage holes, play a crucial role in the functionality and durability of windows. These small openings may go unnoticed by many, but they serve a significant purpose in preventing moisture buildup and ensuring the longevity of window systems. In this article, we will explore what weep holes are, why they are needed, and their importance in maintaining healthy and efficient windows.

0 Comments

When it comes to window frames, there are various options available, each with its unique features and benefits. One popular choice among homeowners and architects is thermally broken aluminium windows.

What are Thermally Broken Aluminium Windows? Thermally broken aluminium windows are specially designed windows that incorporate a thermal barrier or insulation between the inner and outer sections of the aluminium frame. This thermal barrier helps to reduce the transfer of heat and cold between the exterior and interior of a building, thereby improving energy efficiency. How do Thermally Broken Aluminium Windows Work? The thermal barrier in thermally broken aluminium windows is typically made of a non-conductive material such as polyamide or polyurethane. This material acts as a separator between the inner and outer sections of the aluminium frame, creating a break in the thermal pathway. By interrupting the flow of heat or cold, the windows help to maintain a more stable indoor temperature. Advantages of Thermally Broken Aluminium Windows

Remember, consulting with a reputable window supplier or installer such as ALUSMART can provide further guidance and ensure that you choose the right thermally broken aluminium windows for your specific needs. While uPVC windows have many advantages, there are a few reasons why they may not be considered suitable for the Australian climate, particularly concerning the sun and the ozone layer. Here are five reasons:

Speak to Alusmart's technical staff to understand more. In Australia, there are several options for windows and doors screens. Here are five best options:

Thermally broken and non-thermally broken aluminum frames are two types of construction methods used in aluminum windows and doors. Let's compare them:

Consulting with our technical professionals at ALUSMART can help determine the most suitable option for your specific situation. |

Author

Natanael Costea, passionate about Sustainable Smart Homes Archives

Categories

All

|

RSS Feed

RSS Feed